NDE Processes

- Home

- NDE Processes

Non-Destructive Evaluation

Non Destructive Examination is commonly used for evaluating the quality of a part or component using a multitude of processes. Throughout the industry there are various optional procedures for completing NDE, and at TRCW we ensure the most stringent requirements are upheld.

Our team has developed detailed processes in which we must adhere to when validating the quality. of our work. We have invested in industry leading equipment and the experienced personnel to guarantee our customers that industry standards are followed and met. TRCW also employees ACCP/ASNT Level III professionals to oversee documentation and approval of our entire team as well as company procedures.

We complete our examinations so that they’re achieved in a way that prevents damage while also providing scientific measurements that exceed quality in our products.

At TRCW, we utilize NDE techniques to analyze the properties of machined and fabricated products as part of our Quality Control procedures.

Surface Examination Processes

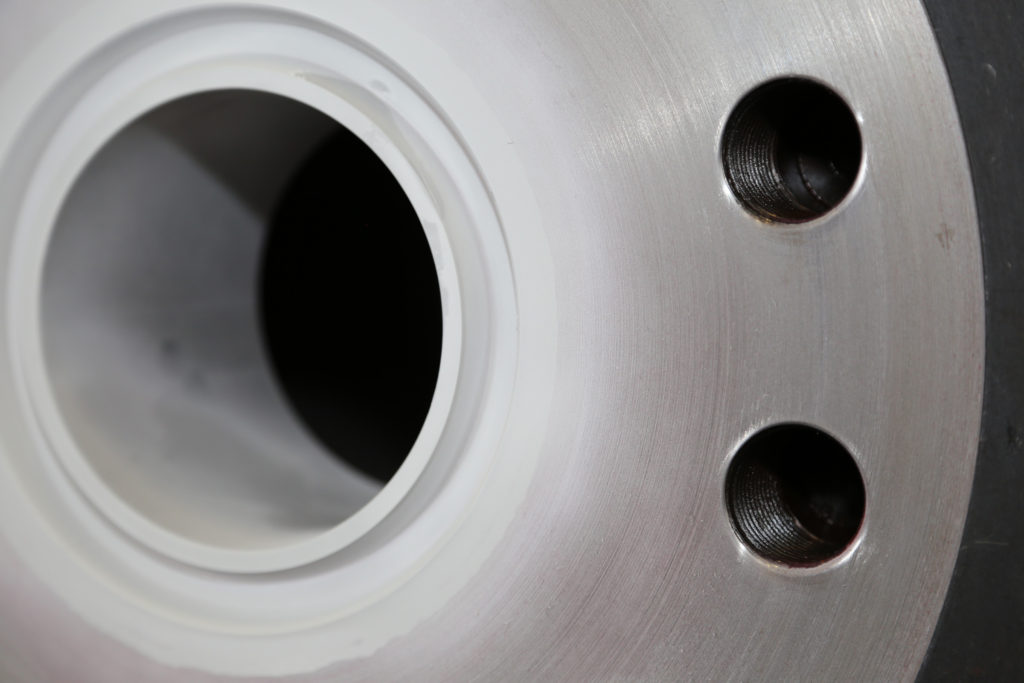

- Liquid Penetrant Inspection

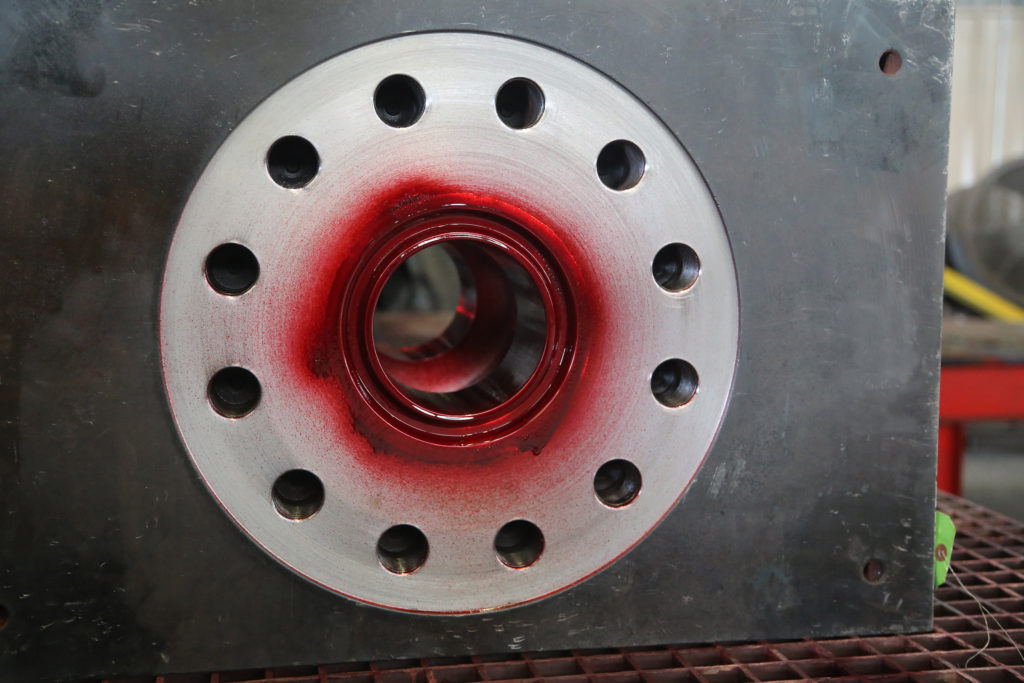

- Magnetic Particle Inspection

- Hardness Testing

- Visual Examination (CWI or ACCP)

- XRF Positive Material Identification (PMI)

- Copper Sulfate Testing

Volumetric Examination Processes

- Ultrasonic Examination

- Eddy Current Testing

Additional NDE Services

- Ultrasonic Examination

- Radiography

- OES Positive Material Identification (PMI)

Quality in everything we do

TRCW provides non-destructive inspection services, providing the technical expertise and experience to maximize the safety, efficiency, and reliability in your critical components and equipment.

Our Houston facility accomplishes this by offering specialized service solutions, industry leading advanced technology and techniques which are performed by our team of highly trained, experienced, and certified technicians.

Now as a Division of Spooltech, we are able to expand our capabilities, to include industrial fabrication, grinding, EDM, gun drilling, prototyping services, as well as numerous other industrial manufacturing processes and operations.

| (UT/RT) Ultra Sonic and X-Ray done by approved outside service |

| (MT) Magnetic Particle Examination |

| Wet Visible Color Contrast |

| Wet Fluorescent |

| Dry Powder |

| (LP) Liquid Penetrate Examination | |

| Water Washable | |

| (BHN) Brinell Hardness Testing | |

| King Brinell | |

| TeleBrinell |

*All NDE services are performed on-site with the exception of Ultra Sonic and X-Ray.

Facility CNC Machining Equipment

NDE Processes

SPECS

94″ Max Swing

67″ Max Cutting Height

33,070 lbs Max Table Load

12 Tool Station

60 HP Table Drive Motor

Doosan PUMA 400L, CNC Turning Center

SPECS

21.7″ Max Diameter

82.4” Max Length

Doosan DBC 130, 5 Axis Horizontal Boring Mill

SPECS

60 HP Motor

1600 mm x 1800 mm Table Size

Doosan 700LC, Turning Center

SPECS

35.4” Max Turning Diameter

126” Max Length

Toyoda FA1050S, Horizontal Machining Center

SPECS

120 Tool Holder Capacity

Hit your project times and budgets!

At every stage we supervise your project – from concept to delivery we remain hands on.